QUALITY CONTROL

DESTRUCTIVE TESTING, LABORATORY, TESTING ROOM

- Introduction to Quality Control in Forging and Smithing

Quality control encompasses a complex set of tests, both destructive and non-destructive, carried out after the forging, smithing, heat treatment, and mechanical machining phases. The goal is to ensure adherence to the technical specifications requested by clients, compliance with industry standards, and certification of components through main inspection bodies, for which Gasparini Forge itself is certified.

- Qualified Experts and Certified Non-Destructive Testing

Gasparini Forge relies on Level 2 technicians, qualified according to ISO 9712 standard ([link to certification page]), experts in performing non-destructive tests, including ultrasonic testing, dye penetrant testing, magnetic particle inspection (contrast and fluorescent), as well as visual and dimensional checks, to ensure the integrity and performance of the processed materials.

- Analysis Laboratory and Testing Room: Precision in Destructive Testing

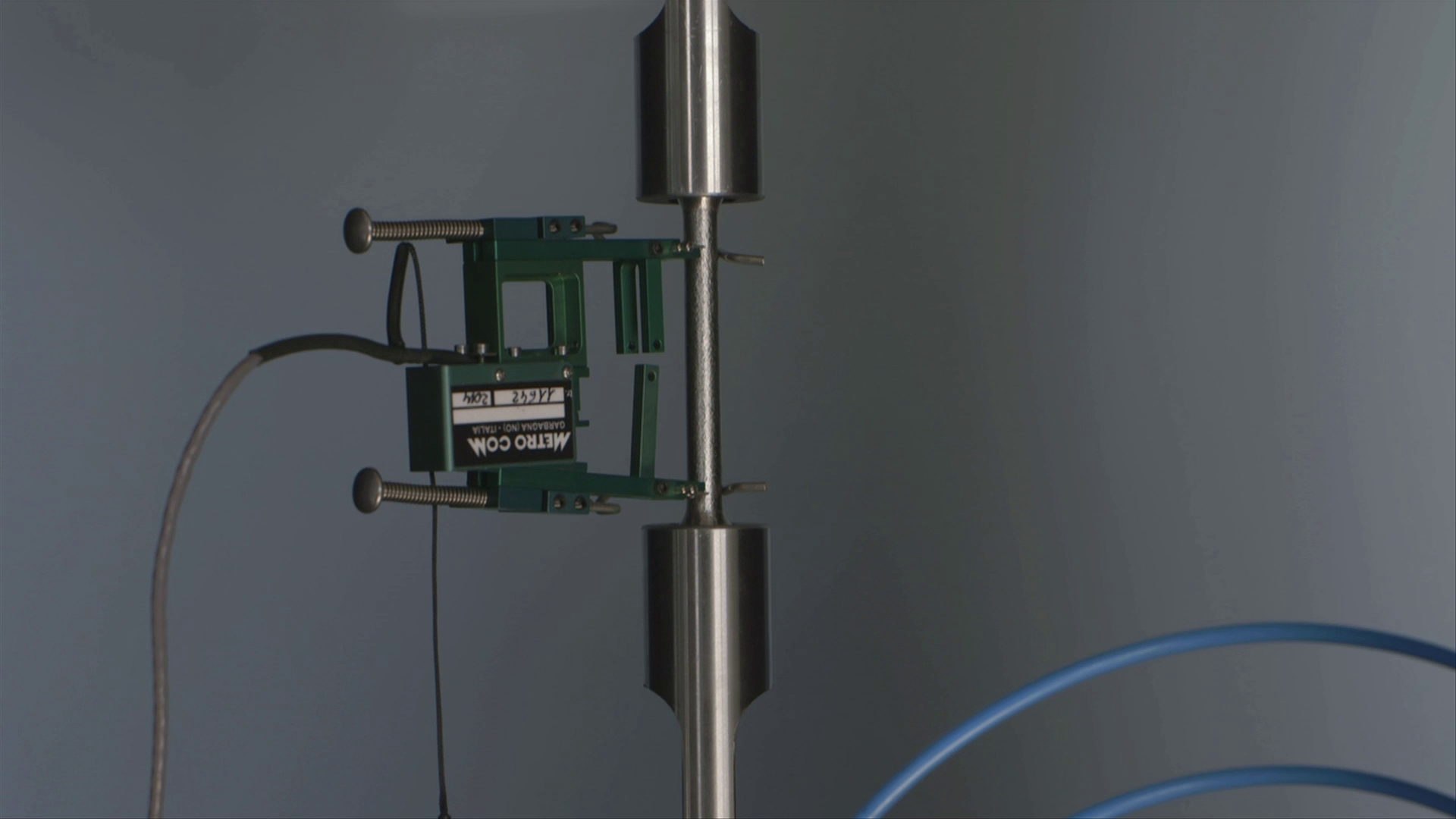

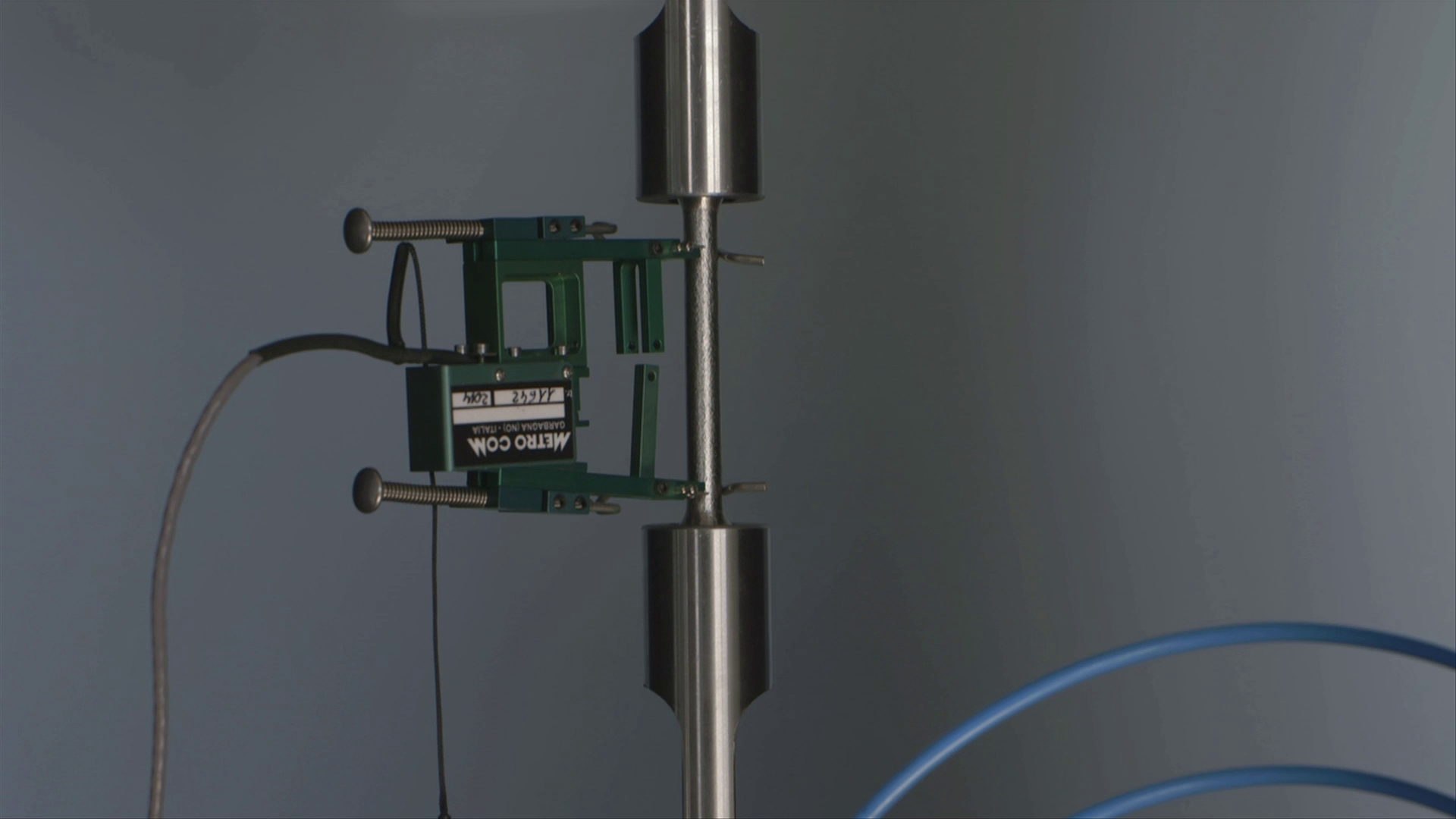

Our analysis laboratory and testing room, accredited for 3.1 and 3.2 tests, are at the core of our destructive testing operations. Here, we conduct tensile testing, resilience testing (down to -50°C), HB hardness testing, metallographic analyses, chemical and PMI analyses, ensuring that the materials meet or exceed the anticipated quality standards.

Discover the Incredible Capabilities of Our Facilities

Charpy Pendulum

Metrocom

Tensile Testing

Metrocom

hardness Tester

Microscope

Spectrometer

Ultrasonic Machine

Portable Hardness